What is the function of anti - ozone coating?

As a coating supplier, I've witnessed firsthand the transformative power of anti - ozone coatings in various industries. Anti - ozone coatings are specialized formulations designed to protect materials from the damaging effects of ozone, a highly reactive gas present in the Earth's atmosphere. In this blog, I'll delve into the functions of anti - ozone coatings, their applications, and why they are crucial for many businesses.

Understanding Ozone and Its Effects

Ozone (O₃) is a molecule composed of three oxygen atoms. While the ozone layer in the stratosphere protects us from harmful ultraviolet radiation, ground - level ozone is a pollutant. It is formed through complex chemical reactions involving nitrogen oxides (NOₓ) and volatile organic compounds (VOCs) in the presence of sunlight.

Ozone is a powerful oxidizing agent. When it comes into contact with materials, especially polymers like rubber and some plastics, it can cause significant damage. Ozone attacks the double bonds in the polymer chains, leading to chain scission, cross - linking, and the formation of cracks on the surface of the material. This degradation can result in reduced mechanical properties such as tensile strength, elongation at break, and flexibility. For example, in rubber products like tires, conveyor belts, and seals, ozone cracking can lead to premature failure, which not only affects the performance of the product but also poses safety risks.

Functions of Anti - Ozone Coatings

- Ozone Resistance

The primary function of anti - ozone coatings is to provide a protective barrier against ozone. These coatings contain chemical compounds that react with ozone before it can reach the underlying material. For instance, some anti - ozone coatings use antioxidants and antiozonants, such as p - phenylenediamines. These substances react with ozone to form stable products, preventing the ozone from attacking the polymer chains of the substrate. By doing so, they significantly extend the service life of the coated materials. - Enhanced Durability

In addition to ozone protection, anti - ozone coatings can enhance the overall durability of materials. They can protect against other environmental factors such as UV radiation, moisture, and chemical exposure. For example, some anti - ozone coatings have UV - absorbing agents that prevent the degradation of the material caused by sunlight. This multi - functional protection means that products coated with anti - ozone coatings can withstand harsh environmental conditions for longer periods, reducing the need for frequent replacements. - Improved Appearance

Ozone cracking can make materials look unsightly, especially in applications where aesthetics are important. Anti - ozone coatings can help maintain the appearance of materials by preventing the formation of cracks and discoloration. This is particularly important in industries such as automotive, where the exterior parts of vehicles need to look good over their lifetime. A well - applied anti - ozone coating can keep the surface smooth and free from blemishes, enhancing the overall visual appeal of the product. - Maintaining Material Properties

As mentioned earlier, ozone degradation can lead to a loss of mechanical properties in materials. Anti - ozone coatings help maintain these properties by preventing ozone - induced damage. For example, in rubber seals, maintaining the proper sealing performance is critical. An anti - ozone coating ensures that the rubber retains its elasticity and sealing ability over time, even in ozone - rich environments.

Applications of Anti - Ozone Coatings

- Automotive Industry

In the automotive industry, anti - ozone coatings are used on a variety of components. Rubber hoses, seals, and gaskets are all susceptible to ozone damage. For example, the engine compartment of a vehicle can have high levels of ozone due to the combustion process. Anti - ozone coatings on these rubber parts can prevent cracking and ensure proper functioning, reducing the risk of leaks and mechanical failures. Also, the exterior rubber trims and weatherstripping benefit from anti - ozone coatings to maintain their appearance and sealing properties. - Aerospace Industry

In aerospace, materials are exposed to extreme environmental conditions, including high levels of ozone at high altitudes. Anti - ozone coatings are used on rubber components such as seals in aircraft engines, fuel systems, and landing gear. These coatings help ensure the reliability and safety of these critical components, as any failure due to ozone degradation could have catastrophic consequences. - Industrial Manufacturing

In industrial settings, conveyor belts, gaskets, and other rubber or plastic components are often exposed to ozone. Anti - ozone coatings can protect these components from damage, reducing downtime and maintenance costs. For example, in a chemical processing plant, where there may be high levels of ozone as a by - product of chemical reactions, anti - ozone coatings on rubber seals can prevent leaks and ensure the safe operation of the equipment. - Consumer Goods

Many consumer goods also benefit from anti - ozone coatings. For example, rubber products like footwear soles, athletic equipment, and household appliances may be exposed to ozone in the environment. Anti - ozone coatings can extend the lifespan of these products, providing better value for consumers.

Our Coating Solutions

As a coating supplier, we offer a wide range of anti - ozone coatings tailored to different industries and applications. Our coatings are formulated using the latest technology and high - quality raw materials to ensure maximum protection against ozone and other environmental factors.

We understand that each customer has unique requirements. That's why we provide customized coating solutions. Whether you need a coating for a specific rubber compound, a particular application, or a specific environmental condition, our team of experts can work with you to develop the right solution.

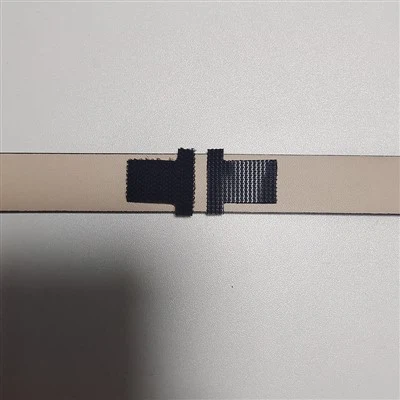

In addition to anti - ozone coatings, we also offer other converting services such as Splicing, Coating, and Rewinding. These services are designed to provide a comprehensive solution for your material processing needs.

Why Choose Our Anti - Ozone Coatings

- Quality Assurance

We have a strict quality control system in place to ensure that our coatings meet the highest standards. Our products are tested in our state - of - the - art laboratories to ensure their performance and reliability. - Technical Support

Our team of technical experts is always available to provide support and advice. Whether you need help with coating application, troubleshooting, or product selection, we can offer the guidance you need. - Cost - Effectiveness

Our anti - ozone coatings offer excellent value for money. By extending the service life of your materials, they can help you save on replacement costs and reduce downtime.

Contact Us for Procurement

If you are interested in our anti - ozone coatings or other converting services, we encourage you to reach out to us for procurement discussions. We are committed to providing you with the best products and services to meet your needs. Whether you are a small business or a large corporation, we have the solutions to help you protect your materials and enhance your product performance.

References

- "Ozone Degradation of Polymers" by M. A. Golub and A. K. Bhowmick.

- "Handbook of Rubber Technology" edited by A. K. Bhowmick and H. L. Stephens.

- "Polymer Degradation and Stability" journal articles on ozone protection in polymers.