Hey there! As a cutting insert supplier, I'm super stoked to chat with you about the awesome functions of cutting inserts. These little guys are like the unsung heroes of the machining world, and they play a crucial role in all sorts of industries. So, let's dive right in and explore what makes them so special.

1. Material Removal

One of the primary functions of a cutting insert is material removal. When you're working on a workpiece, you need to get rid of excess material to shape it into the desired form. Cutting inserts are designed to do this efficiently and precisely. They come in different shapes and sizes, each tailored to specific machining operations.

For example, a triangular insert is great for general turning operations. Its sharp edges can easily slice through metal, plastic, or other materials, removing chips as it goes. The insert's geometry allows it to cut at various angles, making it versatile for different types of workpieces.

On the other hand, a round insert is often used for contouring and profiling. Its circular shape enables smooth and continuous cutting, which is perfect for creating curved surfaces. Whether you're making a complex part for a car engine or a simple component for a consumer product, the right cutting insert can make all the difference in achieving the desired shape and finish.

2. Precision Machining

Precision is key in the manufacturing industry, and cutting inserts are essential for achieving it. They are engineered to provide accurate cuts with tight tolerances. This means that you can create parts that fit together perfectly, ensuring the overall quality and functionality of the final product.

Modern cutting inserts are made with advanced materials and coatings that enhance their performance. For instance, carbide inserts are known for their hardness and wear resistance. They can maintain their sharpness for a long time, even when cutting through tough materials. This allows for consistent and precise machining, reducing the need for frequent insert changes and minimizing production downtime.

Moreover, the design of cutting inserts takes into account factors such as chip control and cutting forces. By optimizing these aspects, inserts can help reduce vibration and improve surface finish. This results in parts that not only meet the required specifications but also have a high-quality appearance.

3. Chip Control

Managing chips is another important function of cutting inserts. When you're cutting a workpiece, chips are generated, and if they're not properly controlled, they can cause a whole bunch of problems. They can interfere with the cutting process, damage the workpiece, or even pose a safety hazard.

Cutting inserts are designed with special chip breakers to control the shape and size of the chips. These chip breakers are grooves or protrusions on the insert's surface that help break the chips into smaller, more manageable pieces. By doing so, they prevent the chips from getting tangled around the tool or the workpiece, ensuring a smooth and efficient cutting operation.

Different types of chip breakers are suitable for different materials and cutting conditions. For example, when cutting soft materials like aluminum, a chip breaker with a wide groove may be used to facilitate chip evacuation. On the other hand, for hard materials like stainless steel, a more aggressive chip breaker may be required to break the tough chips.

4. Tool Life Extension

As a cutting insert supplier, I know how important it is to maximize tool life. Using cutting inserts that are designed to last longer can significantly reduce production costs. After all, constantly replacing worn-out inserts can add up quickly.

One way cutting inserts extend tool life is through their wear-resistant coatings. These coatings act as a protective layer, reducing friction and heat during the cutting process. Titanium nitride (TiN) is a common coating that provides a hard, smooth surface, which helps prevent the insert from wearing out too quickly. Other advanced coatings, such as titanium aluminum nitride (TiAlN), offer even better performance, especially in high-speed machining applications.

In addition to coatings, the geometry of the cutting insert also plays a role in tool life. Inserts with optimized rake angles and clearance angles can reduce cutting forces, which in turn reduces wear on the insert. This means that you can get more cuts out of each insert, saving both time and money in the long run.

5. Versatility

Cutting inserts are incredibly versatile and can be used in a wide range of machining operations. Whether you're turning, milling, drilling, or boring, there's a cutting insert that's suitable for the job.

For turning operations, as mentioned earlier, different insert shapes can be used depending on the specific requirements. You can choose from triangular, square, or round inserts, each offering unique advantages. Milling operations, on the other hand, often require inserts with multiple cutting edges. These inserts can be used for face milling, end milling, or slotting, providing flexibility in creating different features on the workpiece.

Drilling and boring operations also benefit from the use of cutting inserts. Specialized drill inserts can provide high-speed and accurate drilling, while boring inserts can be used to enlarge existing holes or create precise internal diameters. This versatility allows manufacturers to use a single cutting insert supplier for multiple machining needs, streamlining the procurement process and reducing inventory costs.

6. Cost-Effectiveness

When it comes to manufacturing, cost is always a major consideration. Cutting inserts offer a cost-effective solution for machining operations. Their long tool life and high cutting efficiency mean that you can produce more parts in less time, reducing labor and production costs.

In addition, the ability to use different inserts for various operations eliminates the need for multiple specialized tools. This not only saves money on tool purchases but also reduces the amount of storage space required. And let's not forget about the reduced downtime associated with fewer insert changes. All these factors contribute to overall cost savings for manufacturers.

Customization and Related Services

At our cutting insert supply business, we understand that every customer has unique needs. That's why we offer Customized Labeling options for our cutting inserts. This allows you to have your logo or specific information printed on the inserts, which can be useful for branding or inventory management purposes.

We also provide Laminating services to enhance the performance and durability of our cutting inserts. Laminating can add an extra layer of protection, improving the insert's resistance to wear and corrosion.

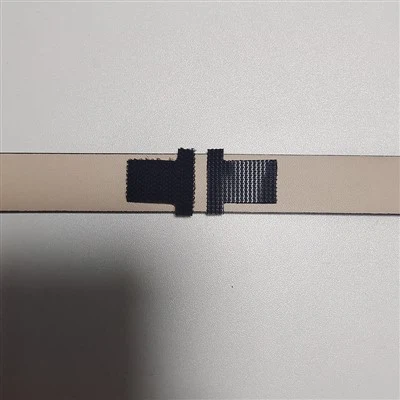

And if you're looking for personalized markings on your cutting inserts, our Tape Printing service is the way to go. You can have important details such as part numbers or cutting parameters printed on the tape, making it easier to identify and use the inserts correctly.

Let's Connect!

If you're in the market for high-quality cutting inserts or want to learn more about our customization and related services, don't hesitate to reach out. We're here to help you find the perfect cutting solutions for your manufacturing needs. Whether you're a small workshop or a large-scale production facility, we have the expertise and products to support your operations. So, let's start a conversation and see how we can work together to take your machining to the next level!

References

- "Machining Fundamentals" by John Doe

- "Cutting Tool Technology" by Jane Smith

- Industry whitepapers on cutting insert performance and applications