Hey there! If you're here, chances are you're dealing with a generator stator that needs some rewinding. Well, you've come to the right place. I'm part of a rewinding supplier team, and I'm gonna walk you through the whole process of rewinding a generator stator.

Understanding the Generator Stator

Before we jump into the rewinding process, let's quickly understand what a generator stator is. The stator is the stationary part of an electric generator. It's basically a bunch of coils of wire wound around an iron core. When the rotor (the rotating part) spins inside the stator, it creates a magnetic field that induces an electric current in the stator windings. That's how generators produce electricity.

But over time, these windings can get damaged. It could be due to overheating, short - circuits, or just plain old wear and tear. When that happens, the generator won't work as efficiently, or it might not work at all. That's when you need to rewind the stator.

Tools and Materials You'll Need

First things first, you gotta gather the right tools and materials. Here's a list of what you'll typically need:

- Wire: You need to choose the right type and gauge of wire for your stator. The specifications depend on the generator's design and power requirements.

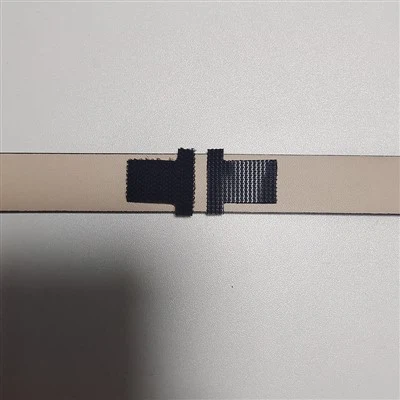

- Insulation Materials: This includes things like insulating tape, varnish, and paper. Insulation is crucial to prevent short - circuits between the windings.

- Tools: You'll need a wire cutter, wire stripper, soldering iron, pliers, and a winding machine. Some of these tools can be pretty specialized, so make sure you get the right ones.

Preparing the Stator for Rewinding

The first step in the rewinding process is to prepare the stator. This involves removing the old windings. It's a bit of a messy job, but it's necessary.

- Disassemble the Generator: Take the generator apart carefully. Make sure you keep track of all the parts and how they fit together. You don't want to end up with a bunch of loose parts and no idea how to put them back.

- Remove the Old Windings: This can be a time - consuming process. You'll need to cut the old wire and unwind it from the stator core. Be careful not to damage the core while you're doing this. Sometimes, the old insulation can be stuck to the core, so you might need to use a solvent to loosen it up.

Winding the New Coils

Once you've removed the old windings, it's time to start winding the new ones.

- Measure and Cut the Wire: Based on the generator's specifications, measure and cut the right length of wire. You can use a wire gauge to make sure you're using the correct thickness of wire.

- Start Winding: Use a winding machine to wind the wire around the stator core. The winding pattern is crucial, so make sure you follow the generator's design. You can find the winding pattern in the generator's manual or by consulting an expert.

- Insulate the Coils: As you wind the coils, you need to add insulation between the layers of wire. You can use insulating tape or paper for this. This helps prevent short - circuits and improves the overall performance of the stator.

Connecting the Coils

After you've wound all the coils, you need to connect them together.

- Solder the Connections: Use a soldering iron to connect the ends of the coils. Make sure the connections are strong and secure. A poor connection can lead to electrical problems and reduce the generator's efficiency.

- Test the Connections: Once you've soldered the connections, test them with a multimeter to make sure there's no short - circuit. This is an important step to ensure the safety and reliability of the stator.

Applying Insulation Varnish

Insulation varnish is used to protect the windings from moisture, dust, and other contaminants. It also helps to hold the windings in place and improve their electrical insulation properties.

- Prepare the Varnish: Follow the manufacturer's instructions to prepare the insulation varnish. You might need to mix it with a hardener or thinner.

- Apply the Varnish: Dip the stator into the varnish or use a brush to apply it evenly over the windings. Make sure all the windings are covered.

- Let it Dry: Allow the varnish to dry completely. This can take several hours or even days, depending on the type of varnish and the drying conditions.

Quality Control and Testing

Before you put the stator back into the generator, you need to perform some quality control checks and tests.

- Visual Inspection: Check the stator for any visible defects, such as loose windings, damaged insulation, or poor solder connections.

- Electrical Testing: Use a multimeter to test the stator's resistance, inductance, and insulation resistance. These tests can help you identify any electrical problems.

- Functional Testing: If possible, test the stator in a test generator to make sure it's working properly. This will give you an idea of how well the rewound stator will perform in the actual generator.

Related Services

As a rewinding supplier, we also offer some related services that can be useful for your generator. For example, we provide Die Cutting services. Die cutting can be used to create custom - shaped insulation materials for your stator. This ensures a perfect fit and better insulation performance.

We also offer Slitting services. Slitting is the process of cutting wide rolls of material into narrower strips. This can be useful for creating insulation tapes or other components for your stator.

And if you need perforated insulation materials, we have Perforating services available. Perforated materials can help with ventilation and heat dissipation in the stator.

Why Choose Our Rewinding Services

There are a few reasons why you should choose our rewinding services. First of all, we have a team of experienced technicians who know what they're doing. They've been rewinding stators for years, so they have the skills and knowledge to get the job done right.

Secondly, we use high - quality materials and tools. We understand that the quality of the materials and tools used in the rewinding process can have a big impact on the performance and lifespan of the stator. That's why we only use the best.

Finally, we offer competitive pricing. We know that you're looking for a cost - effective solution, and we're committed to providing you with the best value for your money.

Contact Us for Your Rewinding Needs

If you have a generator stator that needs rewinding, or if you're interested in our related services, don't hesitate to contact us. We're here to help you get your generator up and running again. Whether you're a small business owner or a large industrial company, we can provide you with the rewinding solutions you need.

References

- "Electric Machinery" by Stephen J. Chapman

- "Generator Maintenance and Repair Handbook" by various authors